Preview of the Member Archive!

The Tampa Bay Automobile Museum to proud to offer this sample page of the 1770 Fardier De Cugnot from the Member Archive! For just $25, you can unlock a treasure trove of exclusive photos, videos, and historical documents that delve deep into the world of automotive history. This 12-month membership offers a unique opportunity to explore the stories behind our remarkable car collection and the visionary engineers and innovations that have shaped the automobiles we know today. Join today and start your exclusive journey!

1770 FARDIER DE CUGNOT

WORLD’S FIRST SELF-PROPELLED VEHICLE

Production Years: 1770

Country: France

Number Produced: 1

Engineered by Nicholas-Joseph Cugnot

Nicolas -Joseph Cugnot ‘s steam powered Fardier (wheeled cart) was the first self-propelled vehicle in the world, making him the world’s first automotive engineer. He had to design and build the first steam engine in which steam, at a higher pressure than atmospheric pressure, drove a piston in a cylinder. He also invented a rotary valve activated by the piston to let the steam in and out of the machine’s two cylinders. The vehicle was demonstrated in France in 1770, pulling a five ton artillery cannon. The original 1770 Fardier de Cugnot has been in the collection of the The Arts et Métiers Museum in Paris, France since 1800.

Our Fardier is a completely functional, faithful reproduction that was created from the ground up by The Tampa Bay Auto Museum and completed in 2010. The engineers from Polypack and Tampa Bay Automobile Museum have given a new lease on life to the Fardier deCugnot. This is the first time that Nicolas Cugnot’s Fardier has run in over 200 years!

Design and Engineering Innovations: At the heart of the Fardier de Cugnot was a groundbreaking steam engine powered by high-pressure steam, a revolutionary technology at the time. This engine featured two single-action cylinders and a four-way valve to efficiently manage steam distribution. The Fardier also utilized a ratchet wheel mechanism to convert the linear motion of the pistons into the rotary motion needed to drive the wheels. This conversion was crucial in automotive engineering, paving the way for more advanced transmission systems in future vehicles.

One of the critical components of the Fardier was its boiler, which initially faced criticism for inefficiencies. However, Cugnot's vision included evolving the boiler design into more effective tubular configurations, significantly enhancing steam production and efficiency. This innovation was crucial in enabling the vehicle to carry heavy loads over various terrains. Furthermore, the Fardier was an early example of a front-wheel-drive vehicle, with the engine mounted ahead of the front wheel, improving traction and maneuverability. Cugnot's vehicle also featured a rudimentary braking system, involving a wooden shoe pressed against the wheel, and a rack and pinion steering mechanism, providing better control and handling.

Historical Significance: Funded by the French Army's Artillery Division, the Fardier de Cugnot was intended for transporting heavy artillery. It successfully carried loads equivalent to a 48-pound cannon, demonstrating its potential for military logistics. The vehicle underwent extensive testing, including a notable trial in November 1770, where it traveled approximately 4.8 kilometers in one hour while carrying a significant load. This trial marked a significant milestone in mechanized transportation.

Challenges and Controversies: Despite its innovative design, the Fardier faced practical issues and limited acceptance during its time. The boiler faced criticism for design flaws such as poor insulation and the lack of a proper safety valve, limiting its efficiency and safety. Additionally, the rudimentary steering and braking systems, weight distribution, and steam production mechanics posed operational challenges that Cugnot and his contemporaries had to address. However, its significance was later recognized, and several replicas were built to honor Cugnot's pioneering work. Today, the Fardier de Cugnot is celebrated as a foundational piece in the history of automobiles.

Fardier De Cugnot Video

Fardier de Cugnot Reproduction

Building the Replica: Tampa Bay Automobile Museum's Tribute

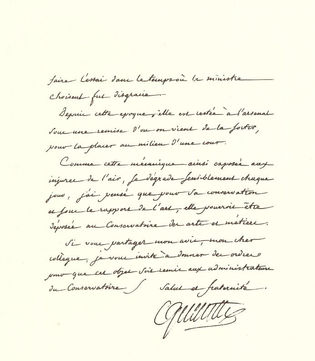

The project began with extensive research into the original Fardier de Cugnot. The museum's team delved into historical documents, drawings, and descriptions of the vehicle. They consulted works such as "Les Éléments de l'Art Militaire Ancien et Moderne" by Cugnot himself, as well as analyses by subsequent historians and engineers. The goal was to understand not just the physical dimensions and components of the Fardier, but also the underlying principles of its design and operation.

Research and Expert Consultation

The museum studied existing replicas, particularly the one built by the Deutsche Bahn Museum in 1935. This model provided valuable insights into the construction methods and materials that could be used. However, the museum aimed to go beyond a simple visual reproduction to create a fully functional replica that could replicate the original vehicle's performance.

To ensure historical accuracy and technical feasibility, the museum consulted with experts in steam engineering, historical vehicle restoration, and 18th-century engineering practices. This collaboration helped in making informed decisions about materials, construction techniques, and modifications necessary to achieve a working model.

The construction process involved recreating the steam engine's cylinders and pistons following General de Gribeauval's original specifications. The boiler design was modernized to address inefficiencies and safety concerns, using steel tubes to maximize heat exchange and enhance safety while incorporating historical elements. The distributor and valve mechanism were meticulously reconstructed, and the steel chassis, wooden frame, and wheels were built to match the original specifications.

Construction Process

Following General de Gribeauval's original specifications, the team produced detailed plans in both imperial and metric measurements. They identified the need to use the "Chatelet toise" for certain dimensions, ensuring historical accuracy. The cylinders were cast using sand molding techniques in Tampa, Florida, and then machined to precise tolerances in the museum's workshop.

One of the most challenging aspects was the boiler. The museum aimed to address the inefficiencies and safety concerns of the original design. They opted for a modern tubular boiler design, with steel tubes running through the water to maximize the heat exchange surface. This approach not only increased steam production efficiency but also enhanced safety.

The team incorporated historical elements, such as using brass tubes for the water flow and ensuring the boiler fit within the original space constraints between the Fardier's outriggers. They also added a safety valve and other modern safety features, respecting the historical design while ensuring operational safety.

Recreating the distributor and valve mechanism was another intricate task. The museum relied on drawings from the Industrial Inventory dating from the early 19th century and incorporated a spring mechanism to accelerate the valve's rotation. This dual-timing system, essential for the smooth operation of the engine, was meticulously reconstructed to match Cugnot's innovative design.

The steel chassis, wooden frame, and wheels were constructed to match the original specifications. The plans were drawn in inches, and hex bolts were used as they were historically accurate. The museum ensured that the various parts fit together logically and securely, replicating the robust construction techniques of the 18th century.

Testing and Refinements

Before using steam, the team conducted initial tests with compressed air. This allowed them to verify the motion of the pistons and the operation of the distributor without the risks associated with high-pressure steam. These tests revealed minor adjustments needed to ensure smooth and efficient operation.

Once the compressed air tests were successful, the team moved on to steam trials. The modern tubular boiler performed admirably, generating sufficient steam to power the vehicle. The Fardier replica moved smoothly, without the jerky motions or vibrations that plagued the original design. This success validated the team's design choices and construction methods.

Public Display and Educational Outreach

The completed replica of the Fardier de Cugnot was unveiled at the Tampa Bay Automobile Museum, now serving as a centerpiece that demonstrates the ingenuity and foresight of early automotive engineering. The museum has integrated the Fardier replica into its educational programs, teaching visitors about the history of steam power, the evolution of automotive technology, and the challenges faced by early inventors like Nicolas-Joseph Cugnot.

Preview of the Member Archive!

The Tampa Bay Automobile Museum to proud to offer this sample page of the 1770 Fardier De Cugnot from the Member Archive! For just $25, you can unlock a treasure trove of exclusive photos, videos, and historical documents that delve deep into the world of automotive history. This 12-month membership offers a unique opportunity to explore the stories behind our remarkable car collection and the visionary engineers and innovations that have shaped the automobiles we know today. Join today and start your exclusive journey!